How It Works

•••

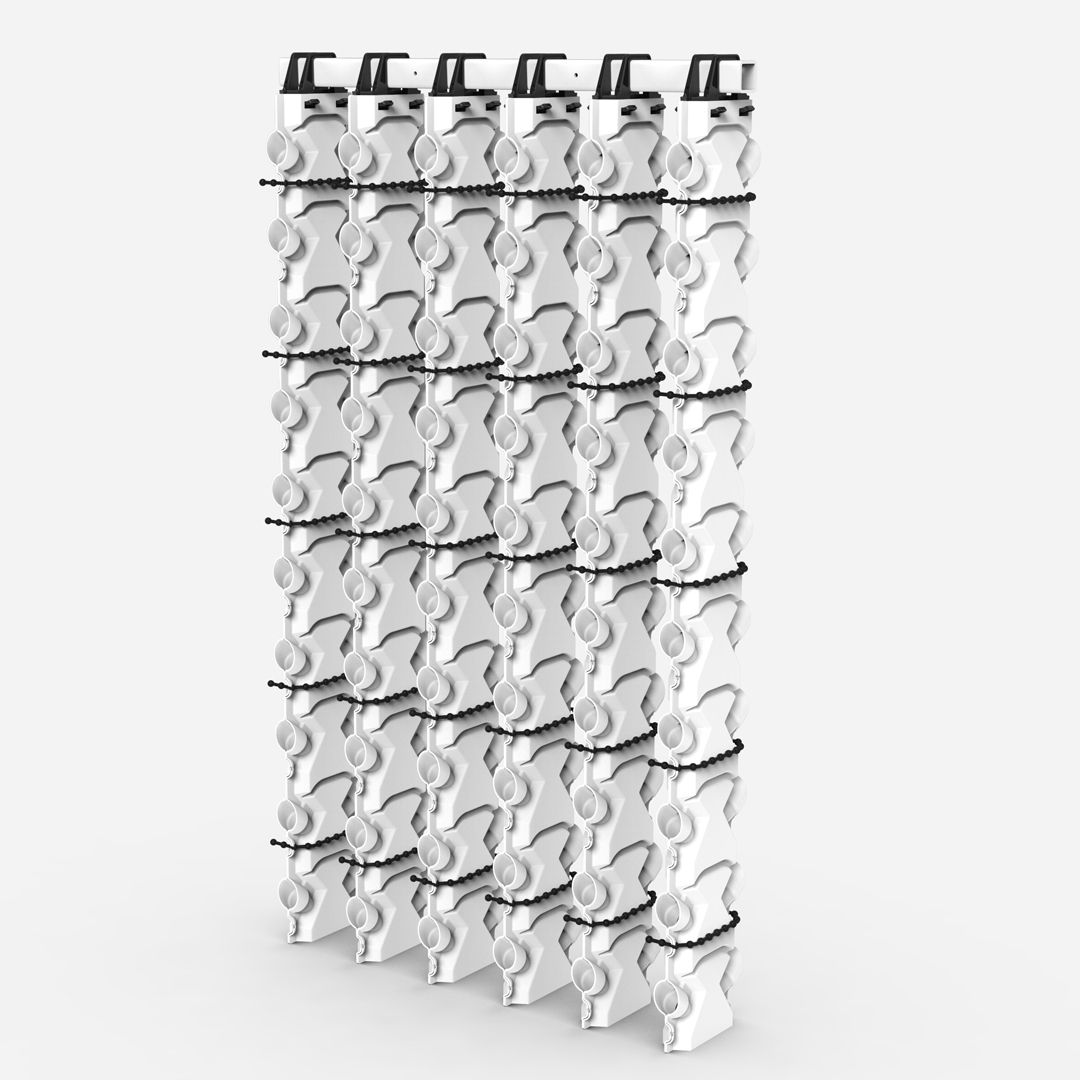

Vertical Grow Towers

High Density Growing

PILLAR-PONICS provides high density vertical grow systems for Aquaponic and Hydroponic gardening. These systems are tailored for both commercial and residential settings.

Vertical towers increase the grow density per cubic foot by 4 to 8 times that of a typical 2-dimensional grow bed.

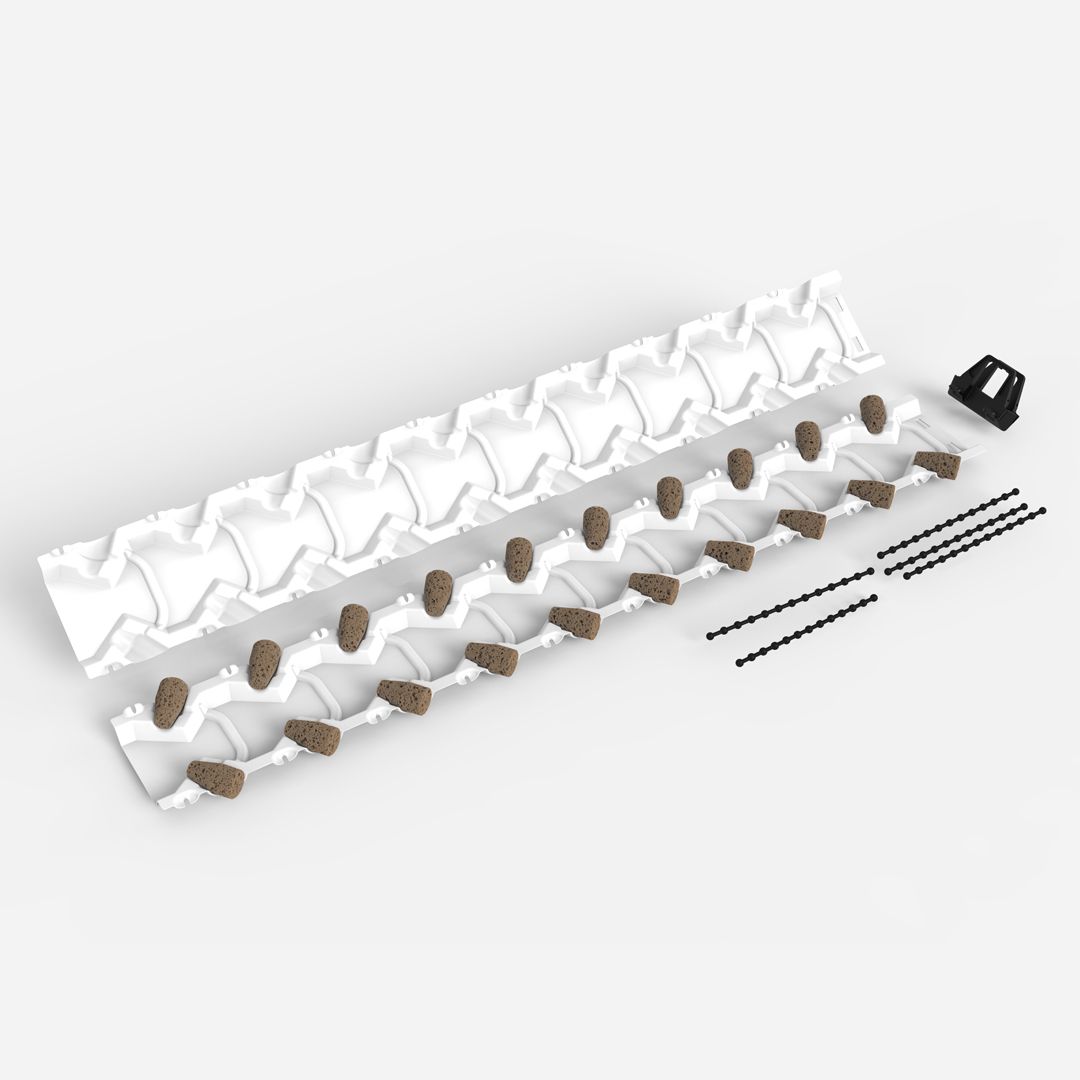

Tower Assembly

Simple Assembly, Simple Harvest, And Simple Maintenance

Separating the tower halves allows the harvesting of the plant, as a whole, with its roots. Harvesting the plant with its roots extends the shelf life of the plant, permits an earlier harvest, and allows for further shipping distances. The clamshell design provides easy access to the interior space, simplifying the cleaning process.

Grow ports accept a variety of different manufacturers grow plugs. Recommended grow plug: ihort 40-80 (ihort.com)

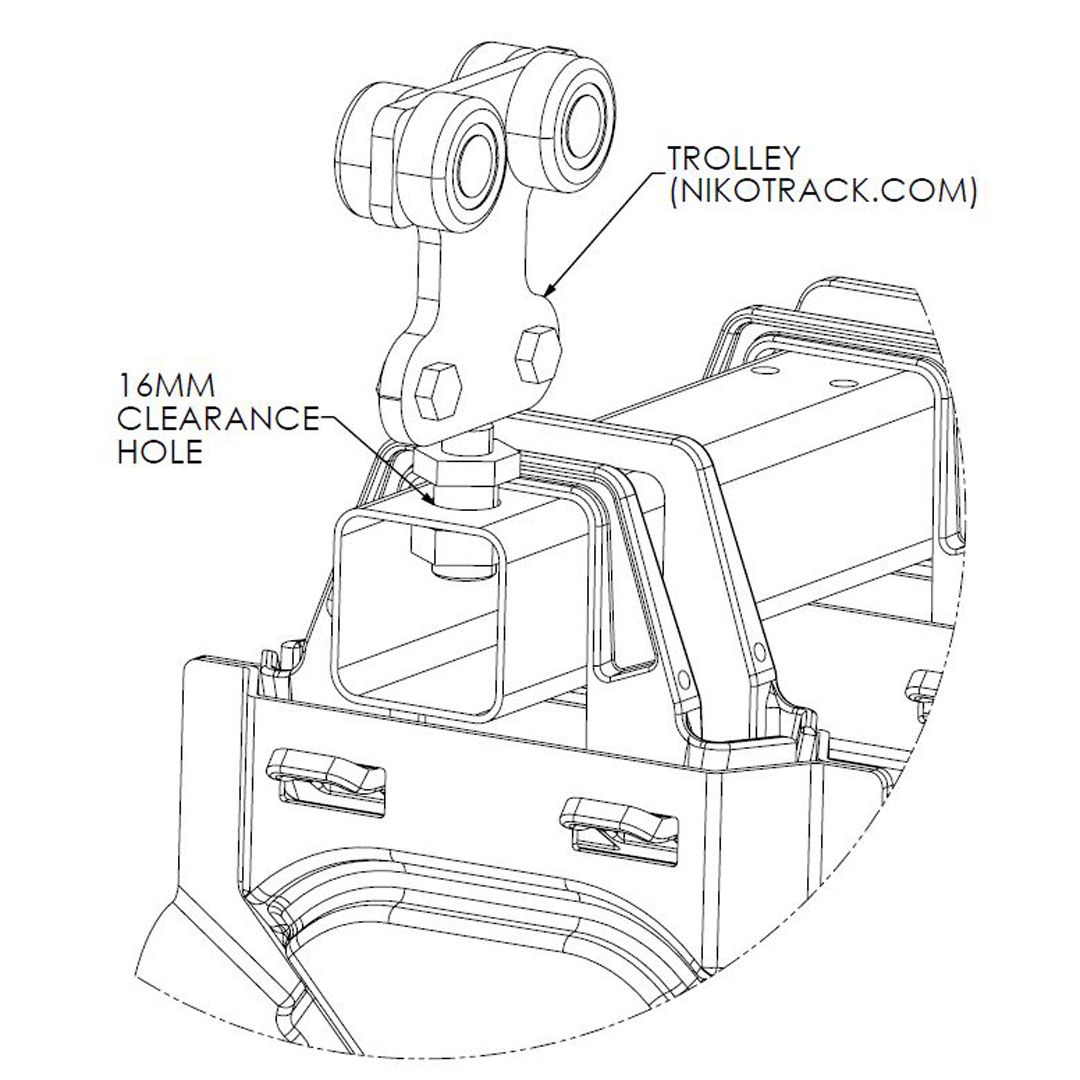

Flight Bar

Modular Pod Overhead Track System Or Suspension System

Trolley And Track

Retrofit To Any Overhead Track System

Commercial greenhouses come in a variety of shapes, sizes, and configurations. Pillar-Ponics does not supply trolleys or overhead track systems but recommends NIKO Track systems (nikotrack.com) or the use of a reputable overhead conveyor manufacturer.

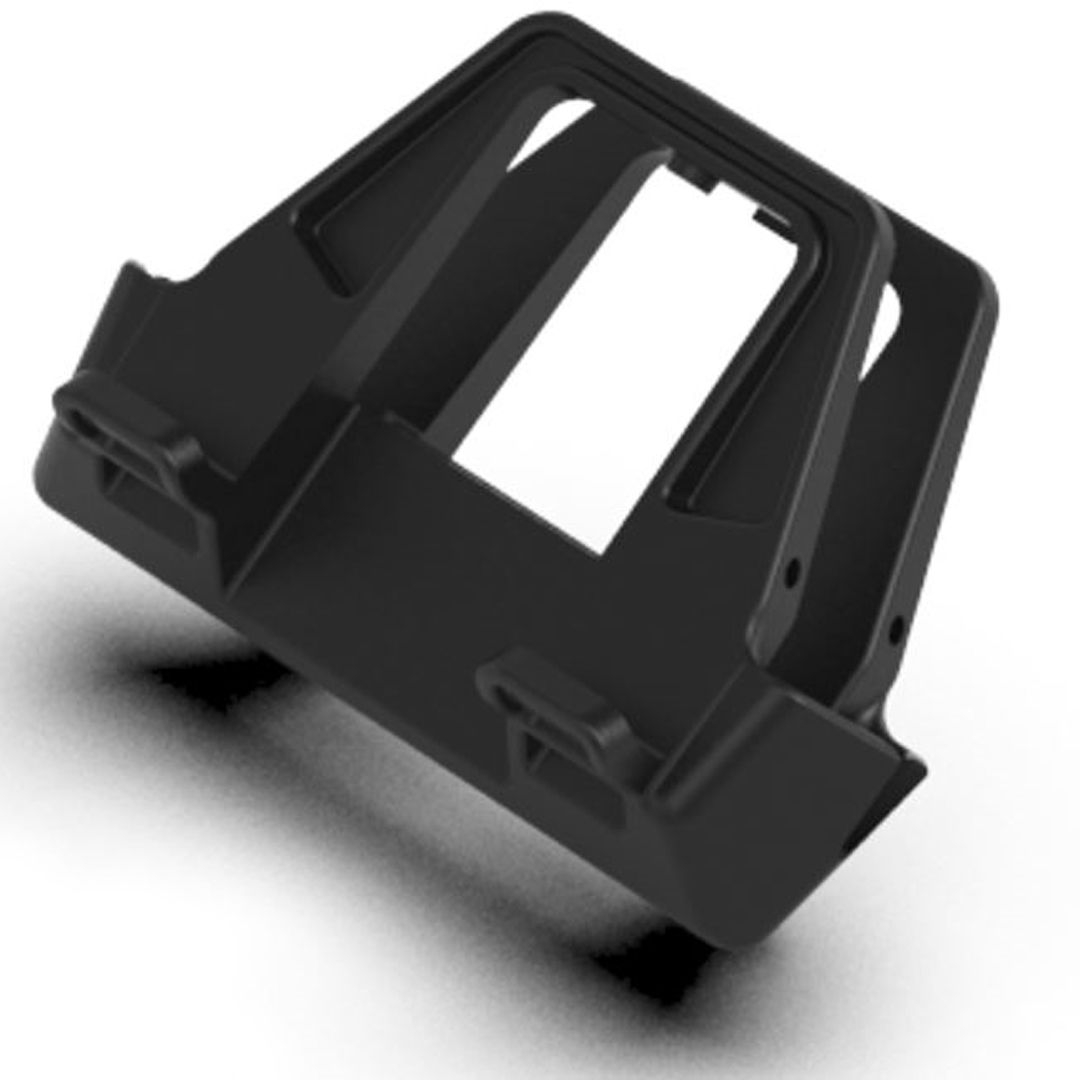

Hangar

Tower Support And Fluid Distribution